Nikalyte specializes in nanoparticles research and development of coating devices to produce nanoparticles.

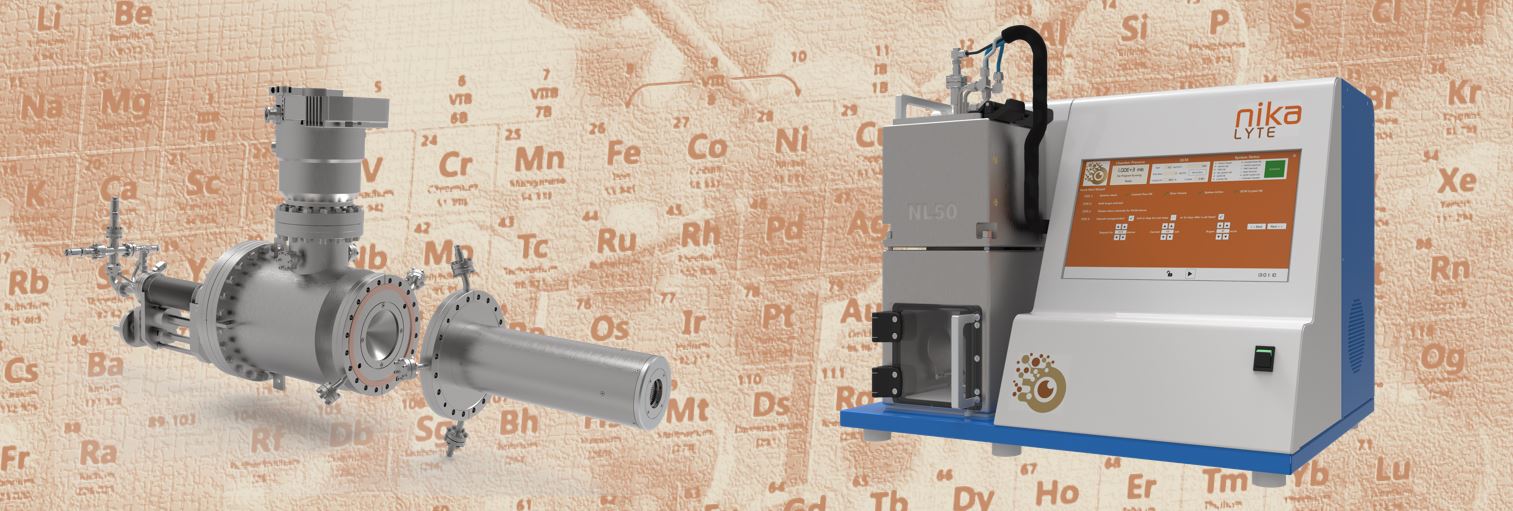

The Nikalyte NL50 is a benchtop nanoparticle deposition system designed for the scientist or technician who is investigating the properties and application of nanoparticles. This instrument produces a coating of nonagglomerated, ultra-pure nanoparticles.

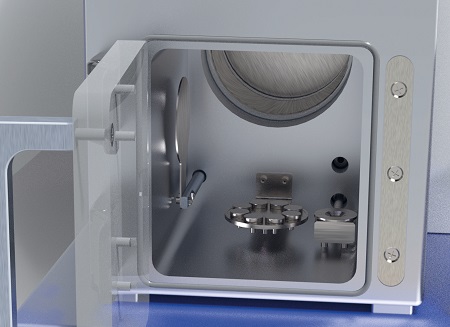

The NL50 is designed to be extremely simple to use, with easy sample loading through a clear sample introduction door and a simple touchscreen for system operation. This instrument will find its home in nanotechnology laboratories throughout the world.

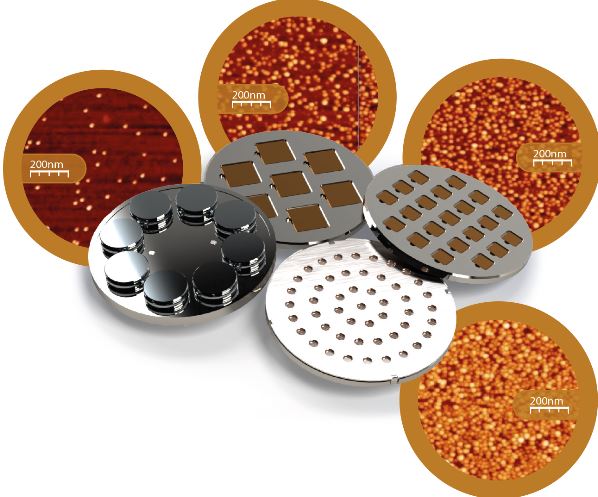

The nanoparticles produced by the NL50 are generated by a magnetron sputtering using a small contained argon plasma to generate atoms of the desired material. These atoms are then thermalized in a very short space of time (<1μs) and form nanoparticles. The nanoparticles are beamed into the deposition chamber through a small aperture and onto the sample. The user is able to vary the size from around 2-20nm (depending on the material) by adjusting plasma power and the flow of argon gas.

The physics behind the technology enables the samples to exhibit an extremely high level of reproducibility and so the potential for inconsistency of ‘wet’ approaches is removed. This is particularly important in laboratories where variations in surface functionalisation can have a large influence on data.

The NL50 also features plasma pre-cleaning technology so that adsorbed molecules are removed and the surface is functionalised to aid adhesion of nanoparticles and any subsequent immobilisation

of molecules.

Application areas include cell binding, cell separation, drug delivery, catalysis, metamaterials, nano-photonics, electrochemistry, batteries and more. Nikalyte Ltd loacted in UK is a global supplier and picovac is proud to support the experienced technical team by offering their services and products in Germany, Austria and Switzerland. Nikalyte can also offer consultancy service which will provide advice on vatious nanoparticle applications.

The Nikalyte NL-UHV instrument range enables the generation and deposition of nanoparticles in Ultra-High vacuum to create a functionalised surface. The properties of the nanoparticle coatings can be tailored through the precise control over the size, composition and structure of the nanoparticles.

The NL-UHV is available with a single 1” or 2” source or a triple 1” source, the NL-DX3. The NL-DX3 allows the deposition of up to three materials either individually, or as alloys using two or three materials simultaneously.

For the ultimate in control of nanoparticle deposition, the Nikalyte NL-QMS mass filter allows the deposited nanoparticles to be scanned or filtered by mass or nanoparticle diameter in real-time, allowing you to optimise the growth conditions. The NL-QMS is controlled via our simple and intuitive software.

Please contact us with any questions around nanoparticles prodcued in vacuum.